Dimensional Accuracy

3D Printing and Dimensional Accuracy

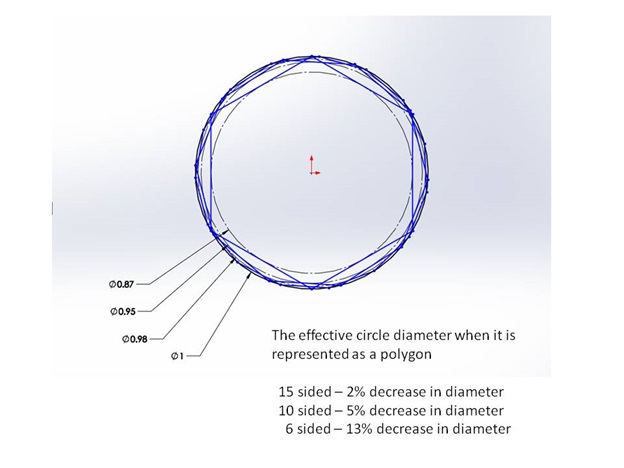

- Effects of poly count on circle precision

- Effects of perimeter order on circle size

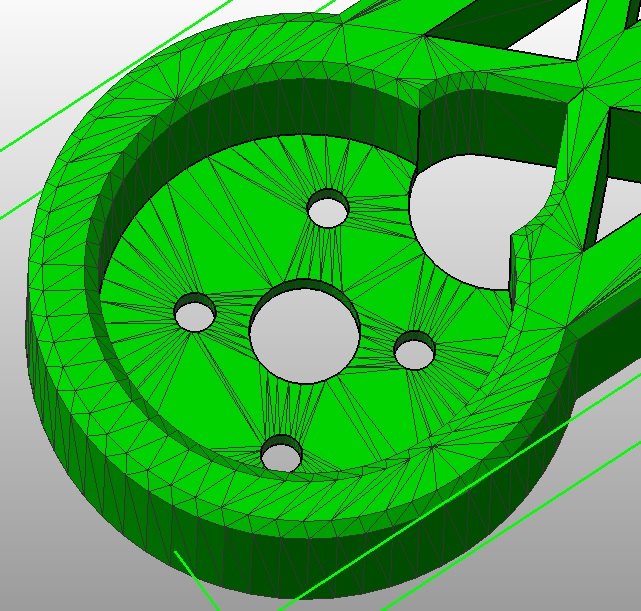

One of the challenges with 3D printing is obtaining the correct size for hole features. Currently the preferred file format for 3D printing is the .stl (Standard Tessellation Language). The STL file format describes 3D images as a series of triangles of various sizes as seen in the figure below.

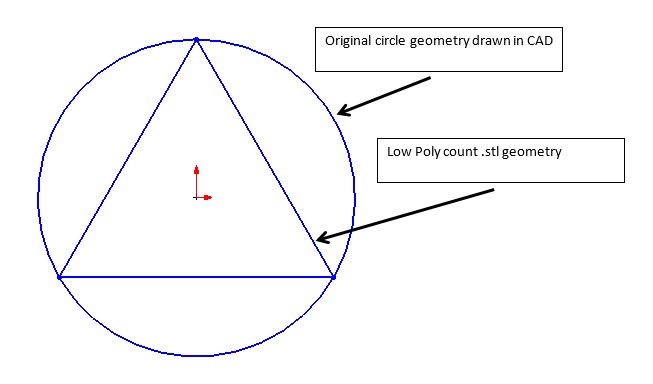

The number and size of the triangles is dictated by the “Preferences” settings of your CAD program. In the extreme example where the CAD model is saved as a “Low Poly count” then the circle or hole feature would be represented by six triangles and the top view would look as the figure below. When 3D printing this circular feature the tool path would follow the triangle geometry and produce a hole much smaller than the original CAD geometry.

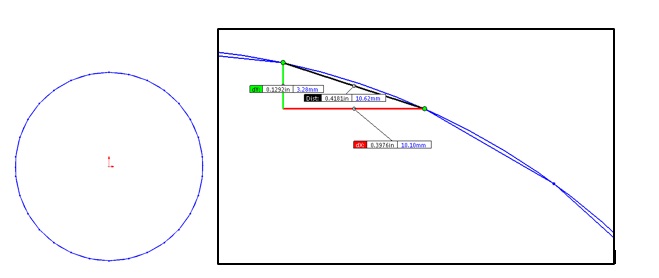

The desire to more accurately represent a true circle would lead to increase the poly count to add more triangles to the model and might look like the below image.

The above image shows a poly count 10x greater than the original “low poly count” example. Increasing the number of triangles does in fact give the 3D printer a better, more accurate circular tool path but at a cost of requiring a higher throughput of data for motion control. If the positional data being fed into the printer has too much resolution

- The machine may not be capable of accurately recreating the resolution or

- The printer controller may not be able to process the positional data fast enough to maintain a decent print speed.

The happy medium is achieved when the poly count is great enough to accurately describe the circle for the needs of the printed part but yet keeping the poly count low enough to allow the motion control system to print the circle at a good speed.

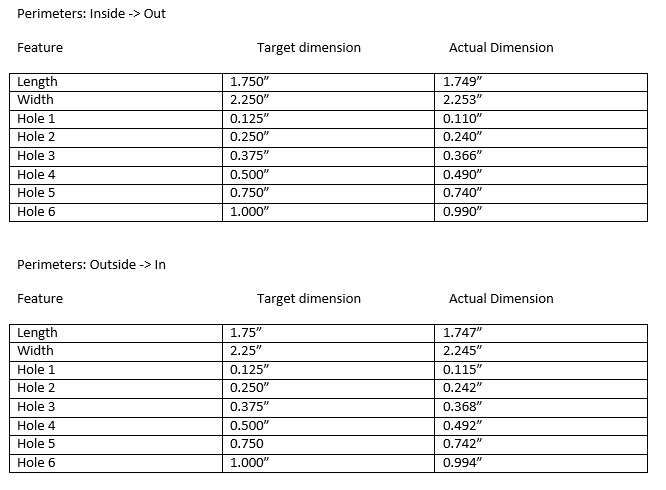

Effects of perimeter order on circle size

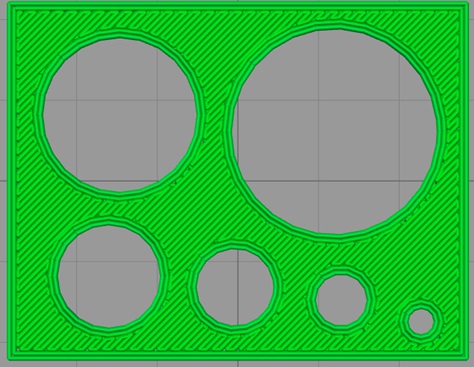

The inside diameter of holes are affected by the order of operations in 3D printing. In the below image the slicer settings have Perimeters = 2. Notice the outside of the box and the inside of the holes have two perimeters. This is often done to strengthen the part and increase the print quality. Most slicing software allow the user to decide if the print starts with the inside perimeter and moves to the outside perimeter.

When starting with the inside perimeter the part has improved surface finish. When starting with the outside perimeter the part has improved dimensional accuracy for holes.

The below image shows the actual tool path for a series of circles with diameters ranging from 1/8” to 1”. Notice that each circle is made from many small line segments.

Actual printed part below.

Also note: Different Slicing programs may also influence the dimensional accuracy of part features.

Additional information on dimensional accuracy in 3D printing [Slic3r Manual]

and here [Designing for 3D printing]