Difference between revisions of "Applying BuildTak print surface"

(→Product Detail and Information) |

(→When installing the BuildTak sheet) |

||

| Line 7: | Line 7: | ||

Expose a small amount (one or two inches) of adhesive on the back side of the BuiildTak by peeling back the plastic film. and position the BuildTak on the bed plate. Slowly remove the plastic film to expose more adhesive while using a rolling pin to flatten the BuildTak into place. The goal is to eliminate any possibility of air bubbles under the BuildTak sheet. | Expose a small amount (one or two inches) of adhesive on the back side of the BuiildTak by peeling back the plastic film. and position the BuildTak on the bed plate. Slowly remove the plastic film to expose more adhesive while using a rolling pin to flatten the BuildTak into place. The goal is to eliminate any possibility of air bubbles under the BuildTak sheet. | ||

| + | |||

| + | [[File:Buildtakongigabot_grande.jpg]] | ||

Revision as of 21:48, 19 August 2014

Product Detail and Information

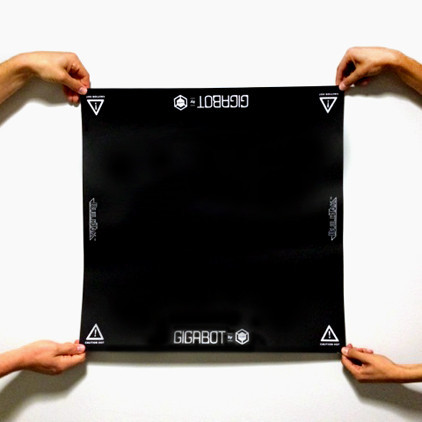

BuildTak is a thin, durable plastic sheet that adheres to the print bed of FFF (fused filament fabrication) 3D printers to provide an ideal surface for 3D printing. It replaces the need for blue masking tape and/or polyimide films such as Kapton. Composed of high quality, heat-resistant raw materials, BuildTak provides a stable build platform for 3D printed objects to adhere to while allowing for a clean, easy removal of completed builds.

When installing the BuildTak sheet

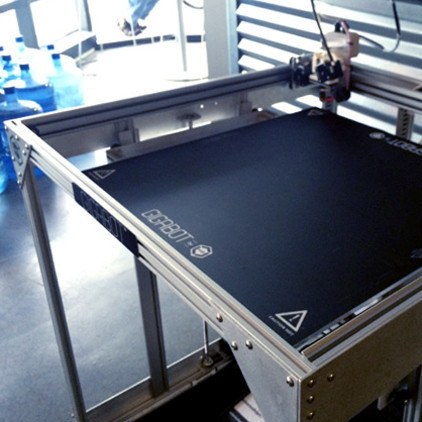

Expose a small amount (one or two inches) of adhesive on the back side of the BuiildTak by peeling back the plastic film. and position the BuildTak on the bed plate. Slowly remove the plastic film to expose more adhesive while using a rolling pin to flatten the BuildTak into place. The goal is to eliminate any possibility of air bubbles under the BuildTak sheet.